Introduction from the Steam Plough Club (SPC) Committee

1. Now that we are in the 21st century, and there are fewer amongst us that remember or have extensive experience of, working engines and tackle in a “live” environment, it seemed an opportune time to record some of the sound advice and lessons learnt for the benefit of all.

2. It is with this in mind that we, the Committee, commend these notes and the guidance contained in the supporting Annexes to all. The aim behind this is to maintain the experience amongst our crews and to spread the lessons learnt by our forebears so that we may operate safely as well as discharging any duty of care to others.

3. Naturally we live in an ever-changing environment, with greater interest being shown by the public in working activities and as such the advice will need to evolve over time. It is also worthwhile to note that several members of the SPC, who worked engines and tackle commercially and who are still very much active have commented that “you never stop learning!”

Context

Transition from working practices to hobby

4. The working of cable steam and diesel ploughing tackle has in the main transferred from a commercial activity to a pleasure and hobby pursuit, with a clear aim of maintaining the currency of skills, demonstrating the activities that helped develop and maintain agriculture across the past century or so.

5. The emerging issue is that instead of working in an environment with few people present, with working practices that were known to whole crews and perhaps a more relaxed approach to health and safety, we now find ourselves working with greater public presence, crews of mixed experience and machinery, which is vintage in nature.

Wider public knowledge and presence

6. The general public are now much more present in working environments than in days of old. The public, in general, is also very much less informed about the safety aspects and working practices of engines and tackle. As such, we must be aware of the gaps in their knowledge and take that into account when working. This is especially true when pulling in an implement, moving forward at the end of a bout or in cases where visibility is restricted. A classic example of this latter aspect is that a front tool box whilst maybe a comfortable seat, with a nicely warmed back on the smoke box door, is not the place to be when the engine moves forward as you cannot be seen by the driver and risk being run over.

7. When we work, we must ensure that we demonstrate safe working practices and spend time, where practicable, with members of the public, in a safe location to explain what is happening and why we operate in the way we do.

Photography

8. One aspect where particular care is needed relates to the use of video cameras or any other camera for that matter, people do have a tendency to put themselves in quite dangerous positions and focus on getting their shot rather than thinking of their own and others safety. Please be aware of what is going on around you. If necessary stop work.

9. On several occasions stopping work has proven necessary whilst in the middle of a pull, which is unfortunate, spoils the spectacle for all, but far safer than someone putting themselves in a dangerous position. Even as recently as last summer, one of the ploughmen working at a demonstration had to stop work and escort a “professional” photographer outside the roped off working area. Not only was he in a dangerous position, but was also potentially drawing members of the public into a similar position

10. The better photographers always make their presence know in advance, make sure they are where you can see them and keep well clear of the working tackle. Working with photographers like this is a real pleasure and some stunning photographs have been achieved. It is just a matter of working together.

Surely this is all just common sense?

11. Yes it is, unfortunately common sense is built around learning, knowledge and analysis of situations. Not everyone both watching and undertaking steam ploughing and working has a sufficient appreciation as to what is safe, what is not, where is safe to stand etc. We must all remember that being human we do not always apply what most would deem common sense to any given situation for example crossing the plough rope when an implement is being pulled in.

Ploughing Engines

What is a ploughing engine.

12. Steam ploughing engines developed during the 19th and 20th centuries to become extremely powerful workhorses. In many respects they are similar to normal traction engines, in that they consist of a locomotive boiler, a gear drive train (not always fitted with guards), and an open crank mechanism. However, under the boiler there is a large winch drum, driven by open gears and a shaft from the crankshaft. This drum holds up to 800 yards of coiled steel wire rope fed through open rollers at knee height to haul an implement back and forwards across the land.

13. Needless to say all those open gears and mechanisms, as well as the use of steel rope under load carries some inherent risk, not least of which are finger or clothing traps. In addition, these engines can weigh upwards of 20 tons or more, move surprisingly fast and quietly and have limited immediate forward visibility due to their bulk. Care is needed.

Know your engine

14. Familiarity with your engine and the tackle is paramount; each piece of equipment and engine is different and behaves differently. This is even true for matched pairs of engines. We must remember that some engines have upwards of over a hundred years worth of wear in them.

15. Knowing your engine well will also enable you to feel subtle changes in working parts and rhythms whilst working. Experience and knowledge also brings an appreciation of the capabilities and limitations of your engine, for example when it will pull a bit harder and when to stop, how to handle the engine under different conditions, where the limitations in visibility and blind spots are, the sound and feeling of a rope coiling correctly and when it is not, which areas require more frequent oiling that others, the vagaries of injectors and capacity for water gauges to sometimes tell interesting tales! Etc.

16. Steam engines are totally unlike just about any other mechanical device; they are almost alive, having “personalities” of their own and are often thought of as akin to large powerful animals. However, this is where the similarity ends, whilst a large animal will often try hard not to injure you, an engine unfortunately does not have that capacity to think, be aware of the warning signs or complacency.

Clothing

General hazards including clothing

17. Appropriate clothing is paramount to safety of the individual, robust boots and long trousers are really a must, you are handling coal, tools near an open fire and hot pipework and near gauge glasses and glands that could leak steam.

- Most crew members wear a bib and brace or a boiler suit, these offer adequate protection and have the added bonus of not having loose ends that can become entrapped.

- Shorts and sandals should be avoided as should thin fabrics or man-made fibres that could melt under heat and offer little or no protection from steam etc. An engine driver, well into his eighties, carried the scars on his legs from a bursting gauge glass in his younger days.

- Long coats or jackets can provide protection from autumnal weather, but you have to be aware that coat edges can become caught in mechanisms and gearing.

- Good footwear is essential. Industrial/working wear type boots, with toecaps are often worn as these provide protection for the feet and adequate grip whilst climbing and descending from the engine as well as in slippery ground conditions.

I learnt about ploughing from that

18. To illustrate the need for some guidance, below, are some examples of some interesting anecdotes:

Eye sight and visibility – Whilst working at an event, the plough crew noticed that in mid pull one of the shares had become detached, kicking the plough out of the furrow. The ploughman signalled for the engine driver to stop, so that the missing share could be recovered and a repair made. Unfortunately, it turned out that the driver’s eyesight was less than perfect and he continued to pull the implement, even after the crew had abandoned ship. Eventually the driver was made aware of the situation and stopped. In comparison, at an event not long ago, a very experienced driver and ploughman, took a look at the field and said that he couldn’t see far enough with his eyesight and elected not to drive the engine.

Signals – Even experienced crews sometimes get confused, and follow signals given by people other than the ploughman. This can expose the plough crew to risk if they are adjusting the plough at the time. Luckily the crew was alive to movements of the tackle and a whistle blast stopped any injury.

Mobile phones and distractions from the crowd/public – The mobile phone whilst useful tool, can be an absolute nuisance, often ringing whilst the driver or even ploughman has his or her hands full and needs to be concentrating on the job in hand. You cannot juggle a plough and a phone at the same time and engine drivers must not be diverted from watching the plough and ploughman, he is their safety net. This coupled with members of the public or even friends wanting to chat whilst the driver is working and pulling in an implement can cause an unwelcome distraction leading to missed signals etc.

Oiling up with the motion running and clothing – Oiling up is only normally at the beginning of the day, or during breaks with the engine at rest. On occasions it has been done whilst an implement is on its return bout. Unfortunately, this can lead to the driver of the idling engine not watching the implement away (a risk in itself) and oiling up whilst the motion is ticking over. This can have unfortunate consequences if ones coat becomes snagged by a key or part of the motion. The driver in question was lucky to get away with a torn pocket and a nasty scare.

Ropes

It is essential that when pulling a rope out, that all understand just how long (or how short) the rope is. It is disheartening to see the rope and the pulley blocks setting off down the field after a well meaning tractor just as you are reaching for the whistle to call a halt.

Whilst attempting to solve a coiling problem on an engine, the rope of an engine was pulled all the way out at an event. Due to the length of the working area, the pulling tractor described an arc across a hillside so that all the rope could be wound off. The first problem to be solved was that the rope had not been properly attached to the drum. The second problem occurred when the engine began to pull the rope back in, as the flag man at a half way point was knocked off his feet from behind by the rope crossing the hill slope to straighten out the arc. Luckily he suffered no injury due to wearing stout boots!

Implements bite – whilst working on a slope in greasy conditions over roughish ground, the tailman attempted to climb onto the plough as it moved off. Unfortunately he slipped and the plough kicked up as he was climbing on, throwing him over the seat and onto the wing of last mould board. Luckily he kept rolling but suffered some bruising and a nasty cut from breast to hip as well as needing a new shirt and boiler suit.

19. The Steam Plough Club commends the following detailed guidance, which can be used with this document or as stand alone documents to aide crews and event organisers. The notes cover the guidelines on safety, working method notes and signals, as well as plot safety. These notes and methods whilst drawing on practices from commercial days have been further developed over the recent SPC challenges and a number of other working events.

Annex A – Guidelines on Safety (an aide memoire for crews and event organisers)

Annex B – Steam Ploughing Signals and Working Methods.

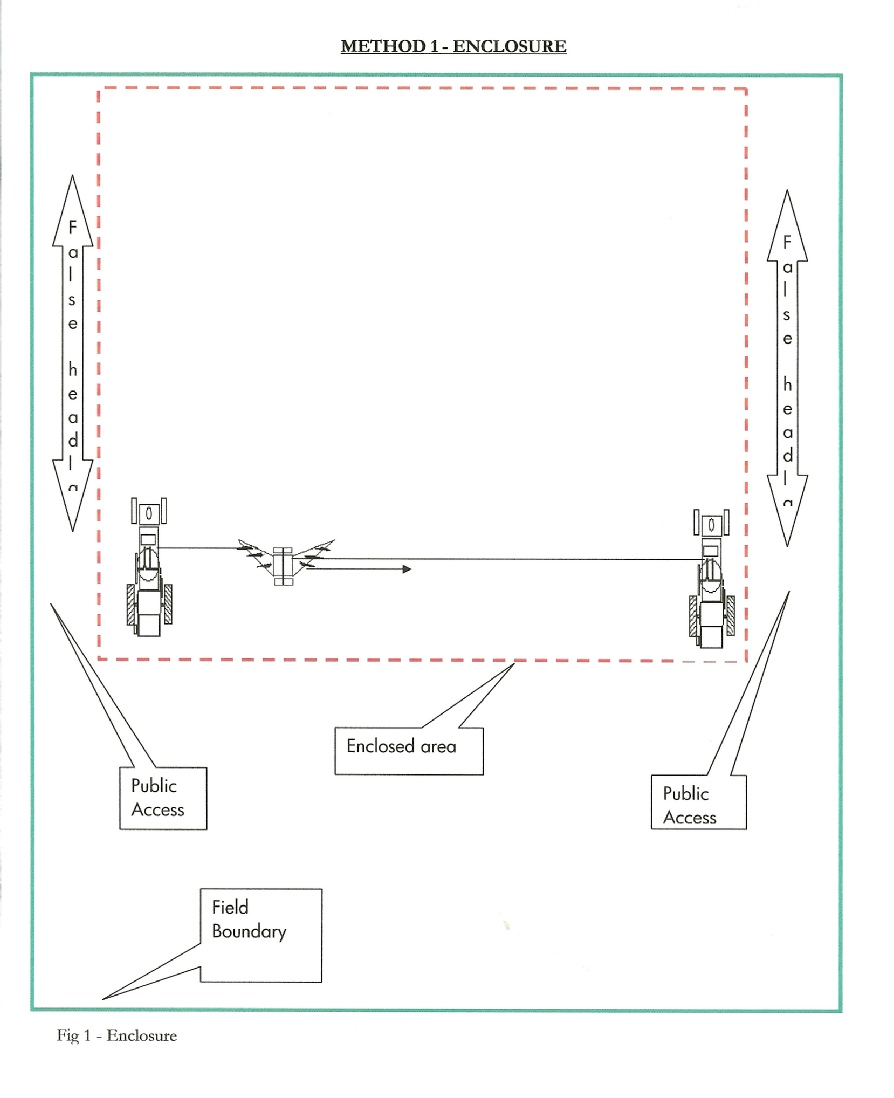

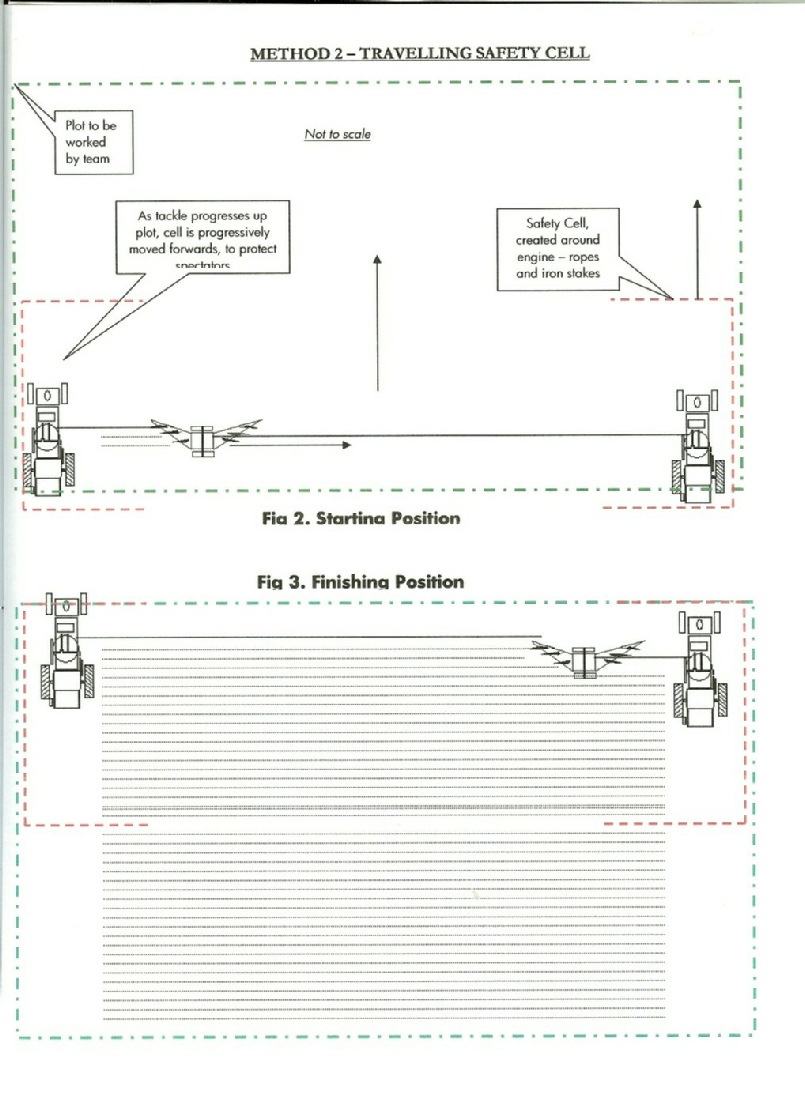

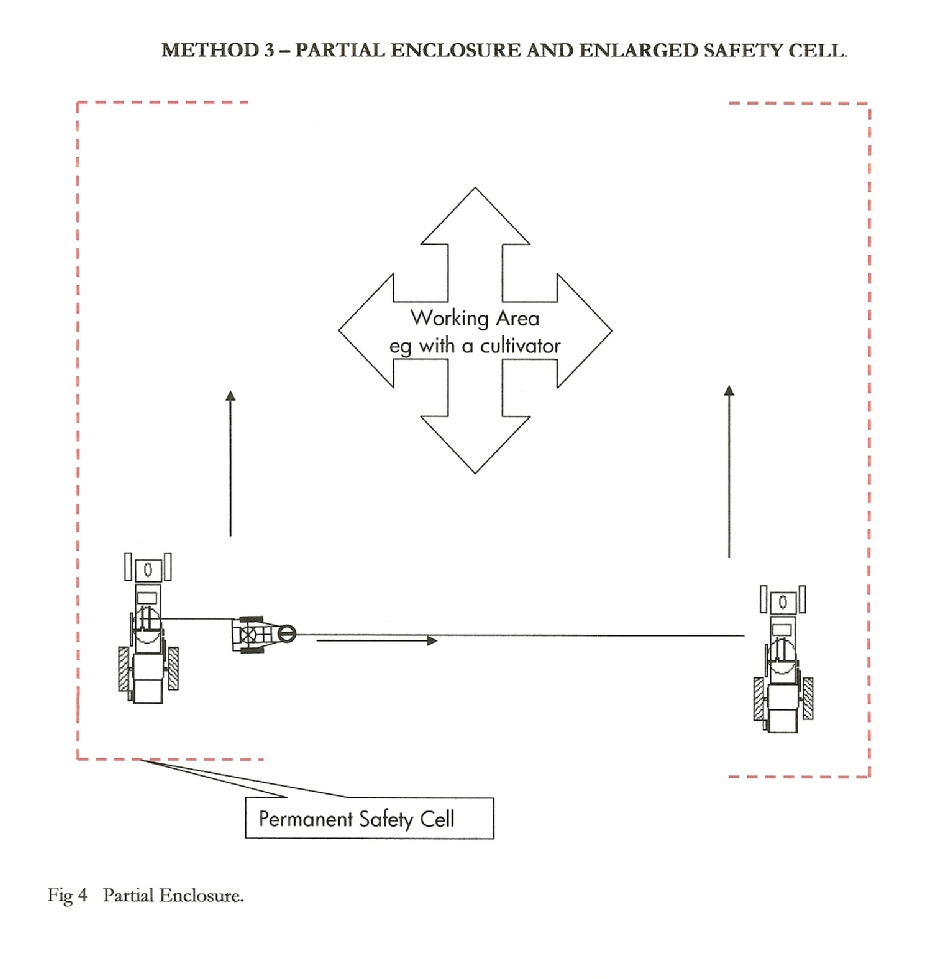

Annex C – Guidelines on Safe Working – Plot Safety